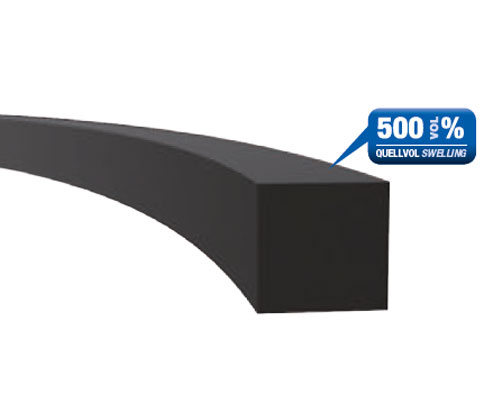

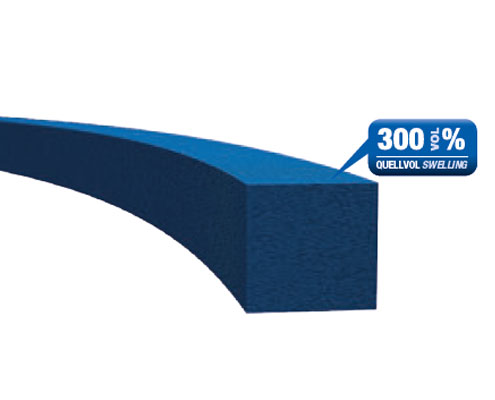

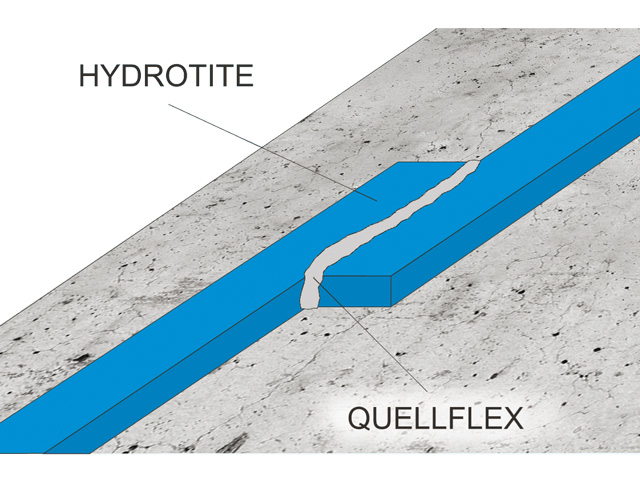

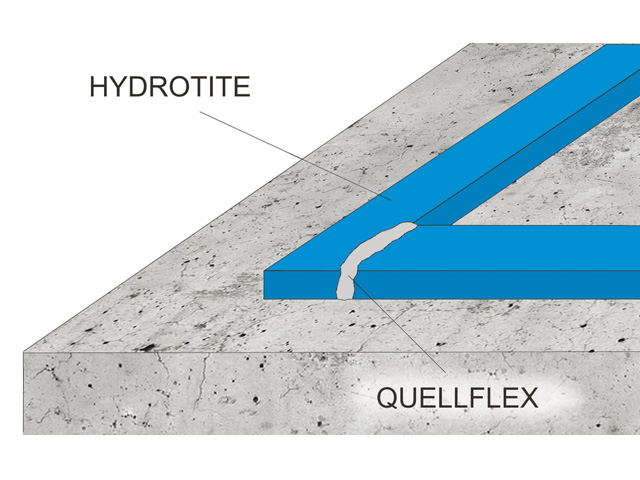

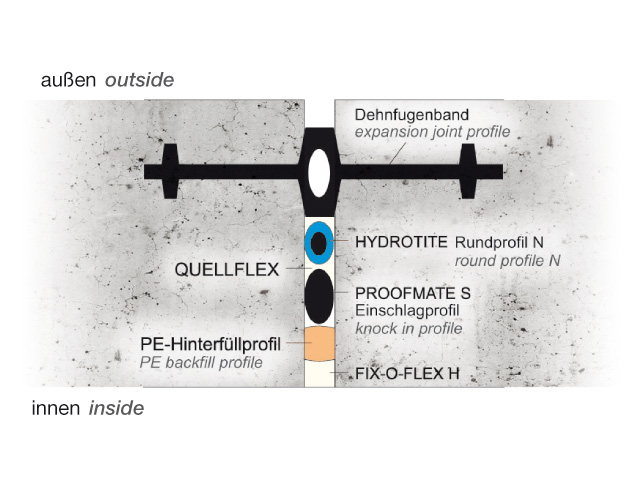

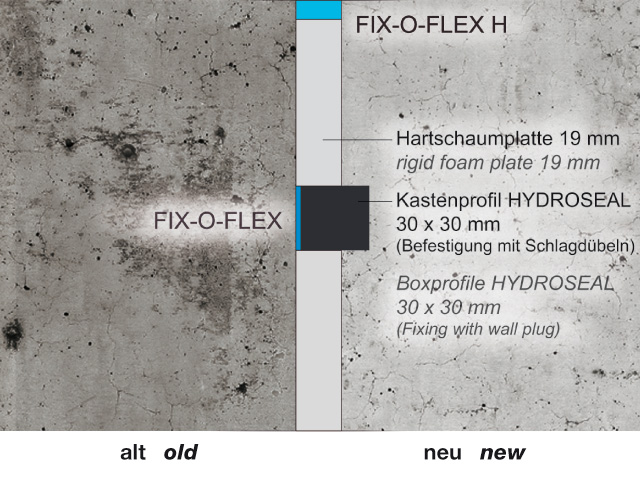

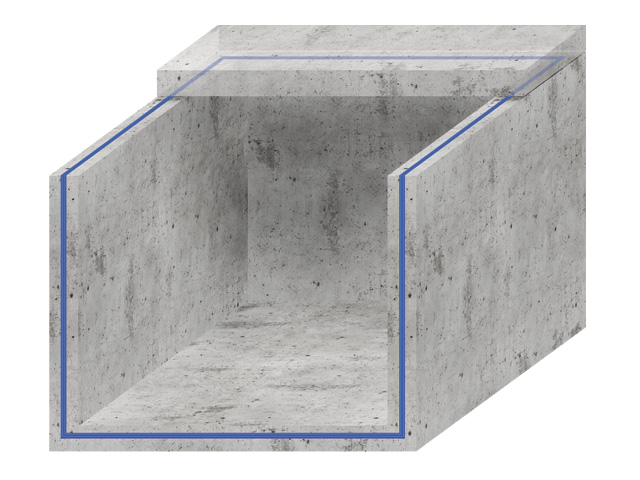

Water-swelling rubber

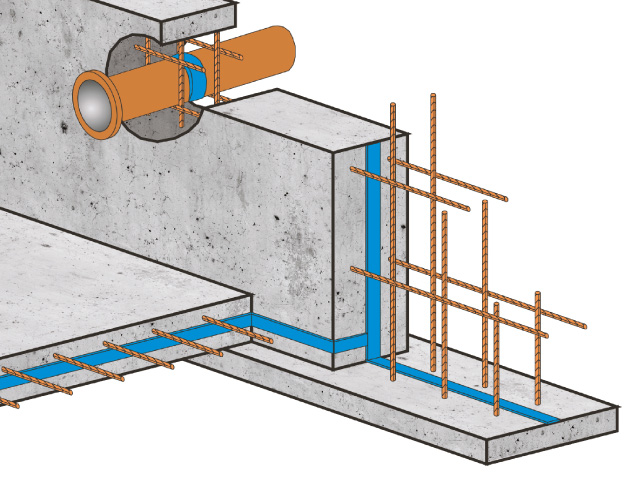

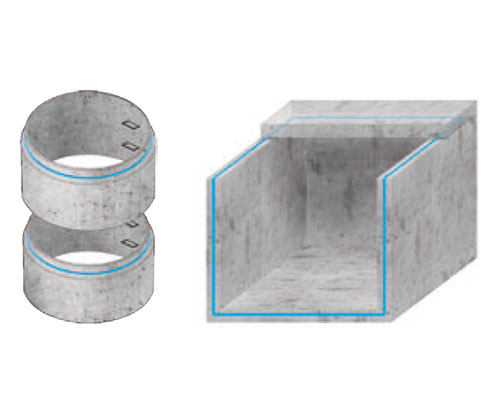

Water-swelling rubber (hydrophilic rubber) is used for sealing of construction joints against pressurised water in reinforced concrete structures. HYDROTITE®, HYDROSEAL and AQUA TACKSEAL® are hydrophilic rubber profiles which are used widely as sealing compounds in structural, civil, construction engineering and tunnel construction. The various hydrophilic rubber profiles stand out especially due to high chemical resistance against acids, alkalis, fuels, mineral oils, organic solvents etc. in addition to its extremely good mechanical properties such as high elasticity and high tear strength. They only differ in the raw material base and the maximum swelling rate.

- Easy processing

- Long-term efficacy

- Also applicable in tidal zones

- High chemical resistance against sewage, manure and chemicals